Cosmic Carbone Ultimate

Mavic a introduit, mi février, une nouvelle paire de roue qui sort des sentiers battus. Après une période de tests intensifs de plus d’un an, les roues

ont sillonné l’asphalte du Tour de France l’an dernier, en guise de test final. Nous avons couvert avec enthousiasme les diverses évolutions des roues et les phases de tests pour présenter en avant

première, ces nouvelles roues full carbone, ou presque.

Comme vous avez pu le constater, ce train roulant ressemble étrangement à son cousin germain: les Lightweight de Carbon-Sports. Il y a fort à parier que le procédé de fabrication soit assez

proche au vu des similitudes. En tout cas, les rayons s’enroulent de la même manière autour du moyeu. C’est une certitude. Toutefois, les différences entre les deux sont bel et bien présentes.

Alors, pâle copie ou véritables améliorations, nous nous efforcerons de porter un jugement objectif sur ces CCU en exposant leurs avantages et

inconvénients.

Cliquez pour agrandir

Comme toutes les pièces carbone haut de gamme, les délais sont très longs. Même si la presse a parfois quelques privilèges pour obtenir des produits à l’avance, force est de constater que pour le

client lambda final, les délais sont toujours excessifs. Mavic, Lightweight, Lew racing pour les roues, THM, BTP, Ax-Lightness pour les composants, tous annoncent des délais atteignant plusieurs

semaines, voire plusieurs mois. C’est la raison pour laquelle nos tests de roues prennent tant de temps à être finalisés.

Les Cosmic Carbone Ultimate affichent un poids officiel de 1185g. Avec une fine couche de colle durcie, notre paire atteint 1200g. Ce qui s’avère léger, mais nous sommes loin des 920g des

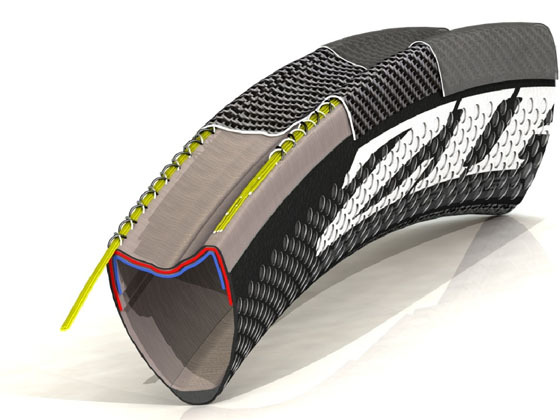

Lightweight ou des 880g des Lew. La trame de carbone utilisée ici est la 12K qui offre une meilleure tenue dans le temps mais aussi une résistance aux chocs moins bonne que les premières versions,

en 3K. Cette trame s’impose, avec le temps dans l’industrie du vélo, pour des raisons d’approvisionnement et de coûts.

|

La fibre de carbone 3K pour les roues de test

|

|

Cliquez pour agrandir

|

Cliquez pour agrandir

|

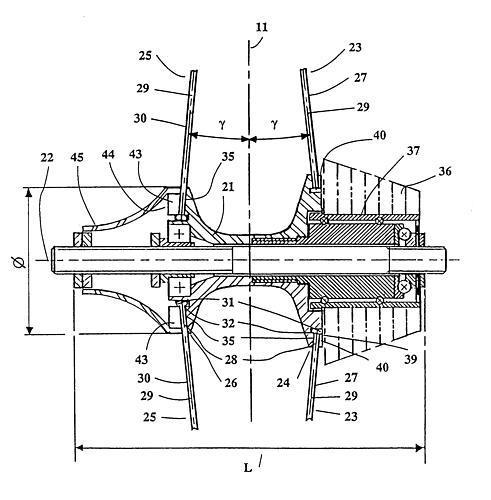

En ce qui concerne le rayonnage, l’avant et l’arrière disposent de 20 rayons. Le côté opposé roue libre de la roue arrière, est un peu spécial puisque les rayons sont radiaux et disposent d’un

système de réglage. Nous en reparlerons plus bas.

Les roues dont nous disposons sont des pré séries datant de février/mars, les versions commercialisées disposent d’un esthétisme revu à la hausse.

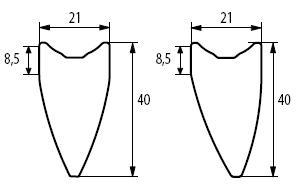

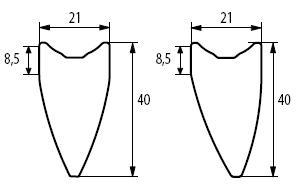

– Les jantes

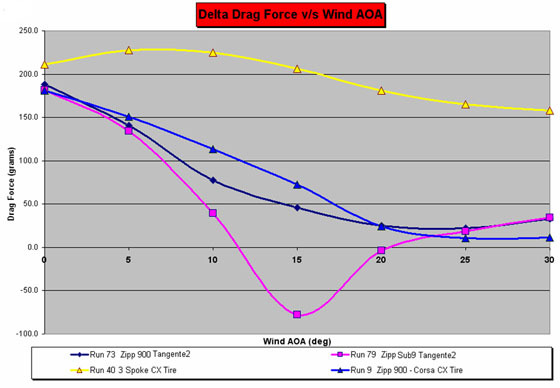

Les Cosmic Carbone Ultimate utilisent des jantes à profil haut de 40mm de hauteur pour 21mm de largeur. La forme des jantes est légèrement incurvée et devrait, en théorie, apporter un

meilleur aérodynamisme qu’une jante triangulaire comme celle des Lightweight. Cette hypothèse sera vérifiée en soufflerie dans les semaines qui suivent.

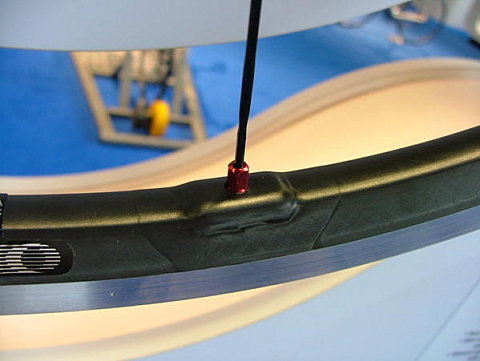

En ce qui concerne la jante arrière, elle est asymétrique pour réduire le déséquilibre entre les tensions des rayons des deux côtés de la roue arrière. L’asymétrie atteint environ 3 à 4mm, ceci est

considérable et permet d’utiliser un parapluie assez large sans trop compromettre l’équilibre des tensions de la roue. On se rend compte de cette conception par le trou de valve moulé qui se trouve

décalé.

Cliquez pour agrandir

En ce qui concerne le look, même si c’est purement subjectif, les stickers sont parfaitement réussis. Il faut souligner que les photos ne permettent pas de se rendre totalement compte de la

valeur ajoutée, en terme de design par ces stickers.

Cliquez pour agrandir

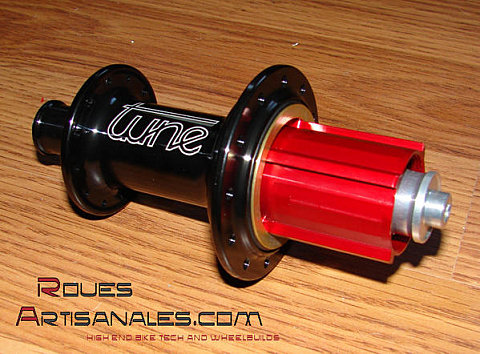

– Les moyeux

Avant

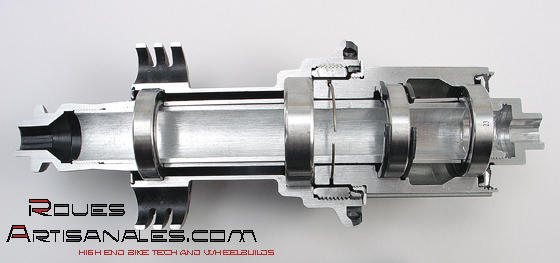

Le moyeu avant est entièrement en carbone, d’une fibre similaire à celle de la jante. La forme est particulièrement travaillée puisqu’il ne s’agit ici pas d’un simple tube. Au centre la section est

très fine ce qui se traduira en léger avantage aérodynamique. Cette partie centrale est collée aux flasques et un léger trait de marqueur indélébile est appliqué pour masquer la colle. Nous pouvons

discerner, entre le flasque du moyeu et le cache extérieur des trâces de colle et de mousse, ce qui semble exactement identique à ce que l’on peut constater sur les Ligthweight.

Cliquez pour agrandir

En terme de finition, ces roues sont en deça de leur concurrent direct Lightweight, alors que nous n’étions déjà pas trop emballés par leur finition. Diverses griffes, rayures et imperfections sont

visibles. N’oublions pas que ces roues sont finies à la main et la paire dont nous disposons est l’une des premières sortie de l’usine. Avec le temps, l’esthétisme devrait s’améliorer et peut être

venir chatouiller les allemandes. Voyez plutôt sur les photos qui suivent les différences en terme de finition et les similitudes en terme de fabrication.

|

Les moyeux des mavic CCU et des Lightweight Obermayer

|

|

Cliquez pour agrandir

|

Cliquez pour agrandir

|

Arrière

Le moyeu arrière est en alliage d’aluminium. C’est assez surprenant quand on a conscience du niveau de gamme auquel ces roues sont destinées. Il s’agit sans doute d’une porte ouverte aux évolutions

futures… d’autant que des modèles à moyeux carbone ont été utilisés par les professionnels lors du Tour 2006. Ils ne disposaient pas du système de réglage. Certes, mais un moyeu en fibres

composites aurait sans aucun doute pu être conçu pour accueillir ce système. Ou inversement, le système aurait pu être modifié pour s’adapter aux caractéristiques d’un moyeu carbone. La roue aurait

gagné quelques dizaines de grammes.

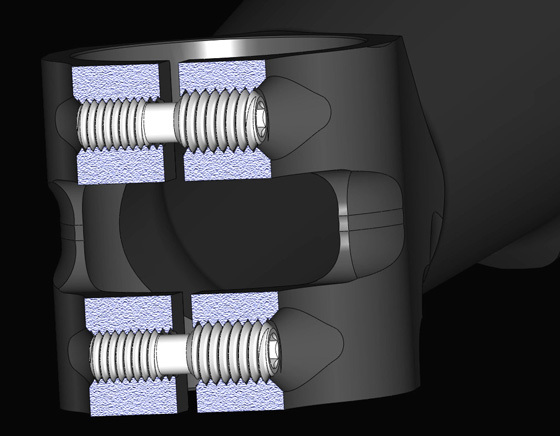

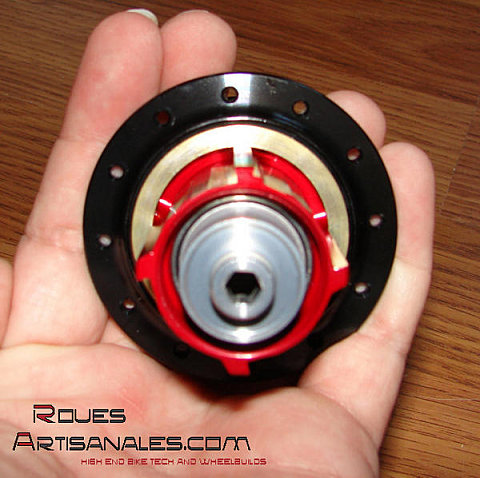

Bref, ce moyeu arrière est réalisé en deux parties. Le corps principal qui comprend le flasque côté roue libre est usiné pour insérer les écrous de rayon du système de réglage lors du montage. La

deuxième partie accueille véritablement les écrous lorsque la roue est montée entièrement. Entre ces deux parties, une bague fine s’intercale pour bloquer fermement les écrous. Ingénieux, mais la

look global de la roue en prend un sacré coup.

Nous aurions préféré un système plus discret avec des écrous entièrement noirs pour coordonner l’équilibre visuel général. D’une pierre, deux coups, l’aluminium aurait allégé le dispositif

(actuellement en laiton) et aurait pu être anodizé pour assortir la couleur noire des roues.

Au niveau de la géométrie, la distance entre les deux flasques qui conditionne en grande partie la rigidité de la roue, est de 55mm. A titre de comparaison, les Lightweight affichent 58mm et les

Lew Pro VT1, 60,61mm. La distance entre les flasques du moyeu des CCU est donc la plus faible des 3. Cependant n’oublions pas que la jante est asymétrique: 3mm de décalage.

|

Cliquez pour agrandir

|

Cliquez pour agrandir

|

Cliquez pour agrandir

|

|

Cliquez pour agrandir

|

Cliquez pour agrandir

|

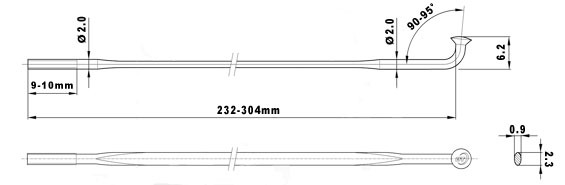

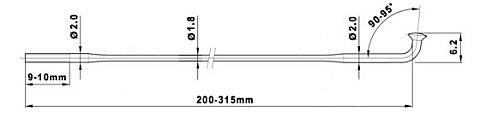

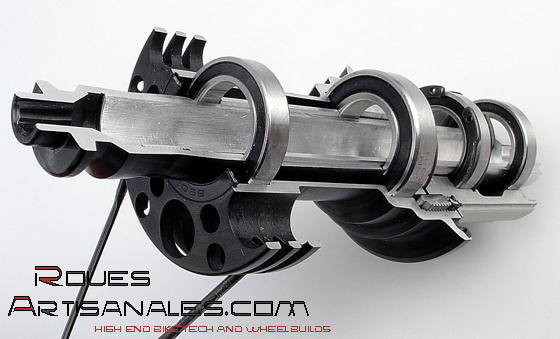

– Les rayons

Formés de fibres de carbone unidirectionnelles, les rayons entièrement noirs affichent des caractéristiques fort intéréssantes: deux fois la résistance d’un rayon traditionnel inox de

diamètre 1,8mm pour 35% de poids en moins, à taille égale. Pour la roue avant, les rayons sont moulés dans la jante, enroulent le moyeu puis rejoignent la jante à quelques centimètres du point

d’origine, à l’instar du cousin germain.

En ce qui concerne la roue arrière, ce procédé de fabrication n’est utilisé que du côté roue libre. Côté opposé, les rayons radiaux sont moulés dans la jante puis vissés au moyeu via un écrou,

comme un roue presque conventionelle. Ce système permet d’obtenir une roue réglable en voile et en saut ce qui s’avère intéressant quand le procédé de fabrication est encore perfectible.

A propos de la tension des rayons, la roue avant n’est pas très tendue. En revanche les rayons de la roue arrière sont de véritables carreaux d’arbalète, et ceci, des deux côtés!

Cliquez pour agrandir

Cliquez pour agrandir

Le point d’insertion du rayon dans la jante

Cliquez pour agrandir

– Un système de réglage… oui mais pourquoi?

La question mérite d’être posée. Le dispositif de réglage tranche avec le look général et ajoute de l’embonpoint. Pourquoi la roue arrière en est-elle équipée alors que la roue avant s’en

passe?

A celà plusieurs réponses et hypothèses, dont une qui sort évidemment du lot. La jeunesse du procédé de fabrication ne permet pas des roues d’une précision excellente, surtout pour une roue

arrière, entraînant un parapluie non symétrique. La roue avant qui s’avère pourtant plus aisée à réaliser n’est déjà pas parfaitement droite ni ronde, il y a donc fort à parier qu’un système de

réglage sur l’arrière était indispensable pour assurer une roue avec un minimum de précision…

En bref…

Sur le papier, le modèle haut de gamme du constructeur français dispose d’atouts fort intéressants face à la majorité des roues du marché. Pourtant, face au son concurrent direct Lightweight,

ses atouts se réduisent au seul critère du tarif (300 euros de moins). En tout cas, en théorie. Nous nous déplacerons à Annecy chez Mavic fin Juillet ou courant Août pour décortiquer chacune des

roues de A à Z: inertie, rigidité latérale et frontale, aérodynamisme, résistance au roulement. Nous espérons d’agréables surprises!

Mavic Cosmic Carbone Ultimate, ~1190g

Cliquez pour agrandir

Cliquez pour agrandir

Complément d’informations

Interview de Michel Lethenet responsable des relations publiques

Pourquoi la forme du moyeu avant a-t-elle été modifiée après le Tour 2006?

M.L: Le moyeu actuel est beaucoup plus aérodynamique et n’était pas prêt pour le Tour 2006.

Un moyeu arrière en carbone aurait été plus sympa, pourquoi avez vous utilisé l’aluminium?

M.L: Le moyeu arrière est en aluminium pour des raisons mécaniques. Un moyeu identique en carbone aurait atteint un poids supérieur à cause des interfaces alu/carbone pour le nez de moyeu FTS-L

(ndlr: système de roue libre) et à cause du système de réglage côté opposé roue libre. De plus, les délais et budgets de conception et de recherche et dévelopemment n’auraient pas été

respectés.

Pourquoi pas de l’aluminium anodisé noir pour le système de réglage?

M.L: Les écrous en laiton sont simplement plus fiables qu’en aluminium. Quant à la couleur noire, les designers n’ont pas cherché la discretion sur ce système de réglage, bien au contraire.

Vous utilisez bien du marqueur pour masquer les imperfections et surplus de colle sur le moyeu avant?

M.L: Il arrive que du marqueur soit utilisé, comme chez tous nos concurrents. Ceci dit, nous en utilisons de moins en moins d’une part, et quand nous en utilisons, il est maintenant plus

discret.

Nous avons du être très patients pour obtenir ces roues, plusieurs mois. Est-ce que les clients devront attendre aussi

longtemps?

M.L: En ce qui concerne les quantités livrées, nous sommes en période de démarrage de production. Toutes les commandes sont concentrées en même temps dans le monde entier. Il nous faut donc

absorber ce pic. Ensuite, vers la fin de l’année 2007, nous serons capable s’assurer des délais similaires à nos autres roues de la gamme. Qui peut en dire autant?