|

Nous n’avions pas encore eu la possibilité d’effectuer d’intensives et longues sorties avec les Lightweight Standard génération 3. C’est chose faîte. Nous nous sommes procurés une

paire en 16/20 afin de les tester sous diverses conditions, et notamment en course, pour les comparer aux autres roues haut de gamme du marché.

Issues des fabrications de Heinz Obermayer et Rudolf Dierl, puis reprises en 2003 par Erhard Wissler à la tête de Carbon-Sports, ces génération 3 bénéficient de presque 15 ans d’expérience

et d’évolution. Autant dire que cette construction semble avoir atteint ses limites et que le produit frôle la perfection à tous les étages.

La perfection, oui, et quelle perfection! Le premier point qui surprend en prenant une paire de Lightweight génération 3 en main, est l’intégration de tous les composants entre eux, et la

finition extrême qui fait de ces roues un petit bijoux, comme une véritable porcelaine de Chine. Point de vis, de trâce de colle, ou de défaut esthétique, ici tout est propre, fin, soigné

en fait.

L’an dernier, nous avions eu la chance de disposer d’une paire d’Obermayer Génération 2, puis génération 3. Force est de reconnaître que les diffèrences, avec la génération précédente, ne

concernent pas que les rayons et leur rigidité. Le produit est bien plus raffiné, élégant d’une certaine manière! Et pour cause, les jantes Obermayer Génération 3 ont carrément une finition

« miroir » du plus bel effet (voir cet article). Les jantes de cette version Standard sont mates mais tout

de même très bien finies.

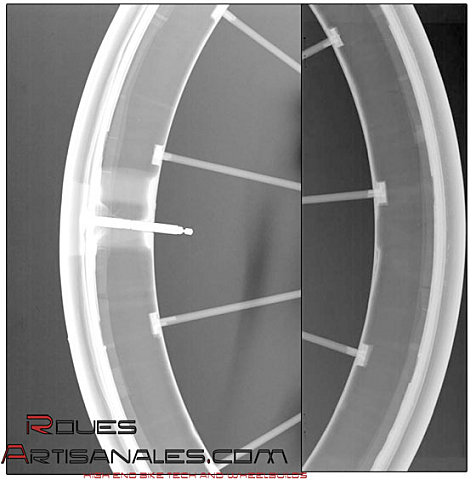

Bref, cette dernière évolution des roues Lightweight reprend donc le concept des doubles rayons moulés dans la jante et enroulés autour du moyeu. La génération 3 met en avant des rayons

entièrement en carbone, donc plus rigides que les rayons hybrides carbone/kevlar de la génération précédente. Le fabricant annonce un gain de 30%. Par la même occasion, les roues semblent

avoir pris quelques grammes au passage mais après tout, quelle importance…? Nous sommes toujours en présence d’un produit aux frontières du kilogramme: 1095g pour être exact, et 990g pour

la version haut de gamme Obermayer.

Sur la route, quelles impressions?

Rigidité/Inertie

Autant le dire de suite: nous étions resté sur une impression moyenne de rigidité latérale de la part des Lightweight Obermayer génération 2, mi 2007. La jante flottait entre les patins et

nous avions eu du mal à comprendre comment autant de commentaires positifs, sur la rigidité de ces roues pouvaient exister.

Le constat est totalement diffèrent sur cette version standard, génération 3. Emmenées par un coureur de 65kg, ces roues font office de fusil de chasse: prêtes à bondir, rigides à n’en plus

vouloir, elles se sont avérées extrêmement performantes. Certes elles sont presque 160g plus lourdes que les Obermayer de notre dernier essai, mais le rapport rigidité/poids est bien

meilleur et c’est perceptible dès les premiers tours de roues.

En course, les sprints sont arrachés avec plaisir et sans perte de puissance. A partir du moment où vous avez des watts à fournir, les roues répondent à toutes les sollicitations.

Cependant, et ce n’est pas rien de le signaler, ces roues s’avèrent extrêment raides et tendent à vous planter si la fatigue s’installe et que les watts ne sortent plus avec autant de

débit…

Les « Standard » sont donc des roues de course, pour coursiers. Elles ne tolèrent que très peu les manques de forme.

Au contraire, la version Obermayer est bien plus docile, le poids de la jante est réduit d’au moins 30g, la rigidité de la roue arrière est bien plus faible et les sensations au guidon sont

totalement diffèrentes: les roues s’avèrent plus « douces » et « agréables » à emmener.

Aérodynamisme et prise au vent

Les Lightweight sont très aérodynamiques. La jante de 53mm et les rayons ovales permettent des performances aérodynamiques excellentes dans des conditions normales. Nous vous invitons à

jeter un coup d’oeil aux tests en soufflerie, sur cet article.

Lors des vents de travers, la force d’Eole pousse la jante avec une surface tellement importante que le guidon « cherche à tourner » constamment. Rien de très dangereux ici, le coureur

s’habitue rapidement à maintenir fermement le guidon.

En revanche les rafales soudaines peuvent s’avèrer bien plus dangereuses car le coureur ne ressent pas la nécessité de maintenir le guidon fermement et il s’écarte donc de sa trajectoire

brutalement. Seul, en campagne ce n’est pas trop grave, quoi qu’il ne faille pas rouler trop près du fossé, mais en peloton, en ville avec des camions, ou autres automobilistes énervés, le

jeu devient plus risqué…

Ces roues sont donc à sortir pour les bonnes conditions climatiques, lorsque le vent ne souffle pas trop.

Nous avons pu remarquer aussi qu’en virage rapide, les Lightweight tendent à nous attirer vers l’extérieur du virage, comme si elles refusaient de virer et nous déportaient. D’après

certains spécialistes, la forme de la jante, légèrement incurvée, et très haute, est responsable de ce phénomène. En course de haute montagne, ce phénomène pourrait être handicapant.

Carbon-Sports a étudié une roue à jante plate en 2005: les Ventoux, pour éradiquer ce phénomène et réduire significativement la prise au vent. Elles sont commercialisés depuis 2006.

Comparatif des quatre paires de roues les plus haut de gamme du marché

Les sensations que nous avons eu sur ces Lightweight Standard, en terme de rigidité et d’inertie sont très proches des Mavic Cosmic Carbone Ultimate. Ces dernières nous laissent

l’impression d’une rigidité encore plus importante et nous avons plus de difficulté à les maîtriser vraiment. De toute évidence les Lightweight Standard et les Mavic CCU sont des roues pour

coureurs forts/costauds d’au moins 70kg de muscles. En dessous, l’idéal est d’utiliser des roues plus légères, plus souples et donc plus dociles.

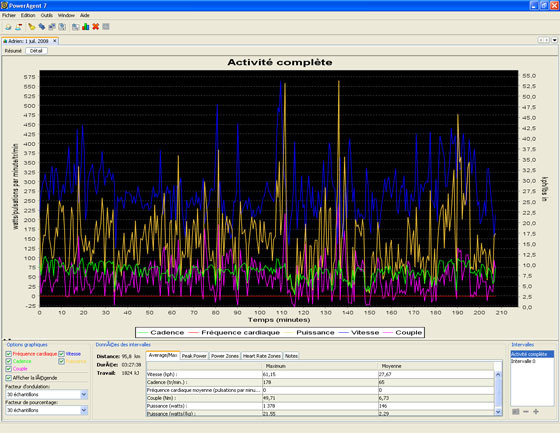

Depuis plusieurs mois, nous avons eu la chance de pouvoir tester les quatre paires de roues les plus haut de gamme du marché, voici donc la table comparative de leur propriétés. Les données

de ce tableau ont été établies à partir de nos sensations sur la route, ainsi que des tests effectués en laboratoire.

Les notes sont données sur une échelle de 5. Plus la note est élevée, meilleure est la prestation

L’échelle de notes prend en compte toutes les roues du marché actuel.

|

Critère

|

Lew Racing Pro VT-1

|

Lightweight Obermayer Génération 3

|

Lightweight Standard Génération 3

|

Mavic Cosmic Carbone Ultimate

|

|

Poids

|

5+

|

5

|

4

|

4

|

|

Inertie de rotation

|

5+

|

5

|

4

|

4

|

Rigidité latérale

avant/arrière

|

2/1

NB: le flasque central transfère le couple et « empêche » les déplacements de la jante entre les patins

|

5+/3

|

5+/5

|

5/5+

NB: la rigidité latérale de la roue arrière atteint la valeur incroyable de 59N/mm sous une charge de 20kg!

|

|

Aérodynamisme

|

4

|

4

|

4

|

4

|

|

Sensibilité aux vents de travers

|

3

|

1

|

1

|

3

|

|

Finition

|

2

|

5

|

5

|

3

|

Fluidité des roulements

avant/arrière

|

5/5

|

5/3

|

4/4

|

4/4

|

Freinage par temps sec

Patins appropriés

|

5

Freinage doux et très puissant, limite brutal

|

4

Freinage excellent, surface de freinage granuleuse/rugueuse

|

4

Freinage excellent, surface de freinage granuleuse/rugueuse

|

4

Freinage excellent et doux (surface de freinage lisse)

|

Freinage par temps de pluie

Patins appropriés

|

4

Très progressif, la couche d’eau disparaît après quelques tours de roue

|

2

Aucune puissance sur les premiers tours de roue, la couche d’eau met du temps à disparaître

|

2

Aucune puissance sur les premiers tours de roue, la couche d’eau met du temps à disparaître

|

2

Aucune puissance sur les premiers tours de roue, la couche d’eau met du temps à disparaître

|

|

Tarif

|

1

|

1

|

2

|

2

|

|

Limite de poids

|

90kg

|

110kg

|

110kg

|

100kg

|

|

Réparation

|

Toutes les pièces sont interchangeables

|

Réparation impossible sauf petit impact sur la jante

|

Réparation impossible sauf petit impact sur la jante

|

Réparation impossible, mais programme MP3

|

|

Photo

|

|

|

|

|

|

Photo by Alessandro Trovati

Photo by Alessandro Trovati

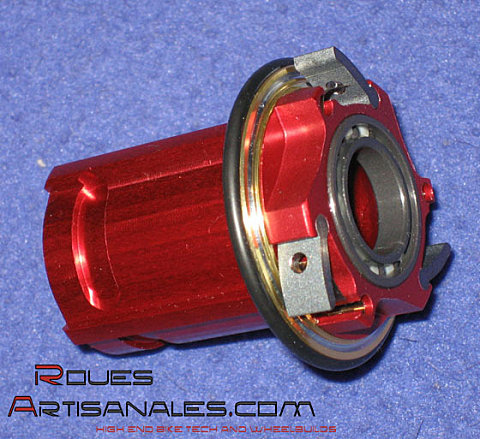

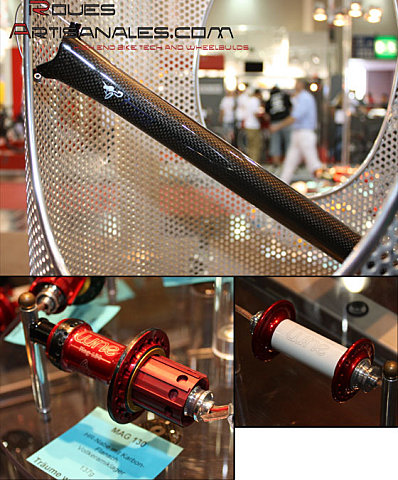

Extralite released the front SX hub some months ago. The italian company is now unveiling the rear version. Straight pull spokes and J bent spokes will be required to build this

Extralite released the front SX hub some months ago. The italian company is now unveiling the rear version. Straight pull spokes and J bent spokes will be required to build this