We have been invited for the presentation of a new wheelset on the shore of Annecy‘s lake. We were pleased to discover the brand new R-SYS introducing the TraComp concept, already patented.

Practically, this system turns out to be totally new and questions the functionning of a bike wheelset. In order to explain clearly the concept, it’s needed to remind how works a conventionnal wheel.

How works a wheel?

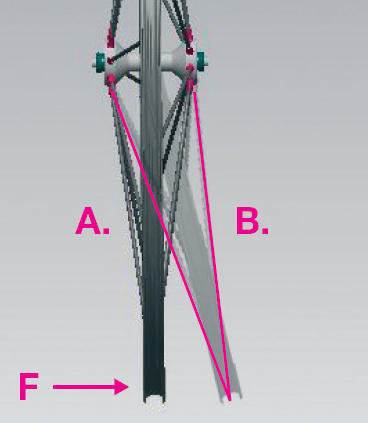

| The integrity of a wheelset is realized thanks to the spoke tension. Each spoke pulls the rim in a direction and, the sum of every tensions solidarizes the rim, the hub and the spokes/nipples. During an acceleration, while standing on the bike or sprinting, a lateral force is applied on the rim (F on the drawing) so the wheel gets out of shape, more or less according to its lateral stiffness. The spokes on the same side as the applied load get more tension (A spokes on the drawing) while the ones on the other side lose tension (B spokes). Below is a picture of loose spokes because of a high load applied on the rim. Click to enlarge

|

Photo © Mavic |

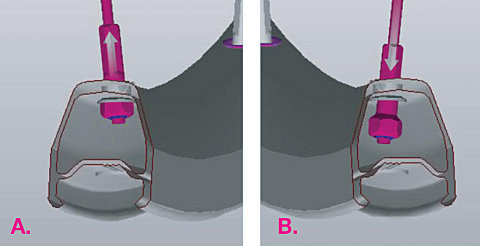

| When a very high load is applied, the nipple of the spoke losing tension leaves its bed (picture B) which is either the eyelet or the internal wall of the rim. First consequence: in most cases, the nipple profits of this motion to rotate around the spoke (screwing down) so the wheel gets out of true.Second consequence: the wheel lose a lot of rigidity because there is only the spokes of one side that resist to the load. |

Photo © Mavic

|

TraComp concept wheelset behavior under a lateral load

The spokes are screwed up inside the rim, just like a standard Ksyrium ES. So they are firmly blocked and, any play inside the thread is removed thanks to a blocking compound. At the hub, the spokes are blocked too thanks to an alloy ring that is both stiff and resistant to compression.

Thus, when a high lateral load is applied, the spokes that get loose on a conventionnal wheel, enter in compression. This phenomenon is possible thanks to two things. The tubular carbon very stiff spokes do not bend under the strain. They are way stiffer than standard stainless steel spokes for example. If flexier spokes would have been used for this system, they would simply bend and the concept would be useless.

Then, the low tensions in the spokes make the entry in compression easier. With high spoke tensions, the concept would be useless since the spokes losing tension because of the load, would still be slightly under tension.

Last but not least, the low spoke tensions stress much less the wheel components so they can be enlightened.

To give some figures, thanks to this system, Mavic has been able to use sub 400g rims. Ok, there are still lighter alloy rims on the market but the standard for a complete wheel is excellent.

Unidirectionnel carbon fiber spokes are round and hollow. The external diameter is 4mm, the internal one is 2.6mm. Their weight is around 5g each which is similar to a long Cx-ray (for flat rims) and way lighter than a 7g Ksyrium ES spoke. The wheelset weight is 1355g in clincher version and 1340g for tubulars.

The TraComp system has the particularity to allow low spoke tension. Thus, it’s possible to design a wheel with a high bracing angle to increase the lateral stiffness without sacrificing the spoke length of life or the wheels settings. Compared to a Ksyrium ES, the non drive side flange is 4mm closer to the dropout.

The spoke tensile resistance is higher than standard spokes. It’s between 300 and 500daN which is better than the 260daN of a Cx-ray. Their stiffness is exceptional and, it allows a good stiffness as a complete wheel. According to Mavic, the spoke number and their stiffness role is up to 36% on the overall wheel stiffness. As information, the rim is only about 10% and the bracing angle is almost 50%…

To get more stiffness again, Mavic had another solution: reducing the internal diameter of the spokes, or even using a full carbon rod. The stiffness would have been 18% higher for a weight increase of 42% per spoke, meaning 60 more grams a wheelset.

The lateral stiffness of these new R-SYS is up to 56N/mm for both front and rear wheels. As a comparizon, the Lightweight Standard are, respectively for the front and rear, 60 and 43N/mm.

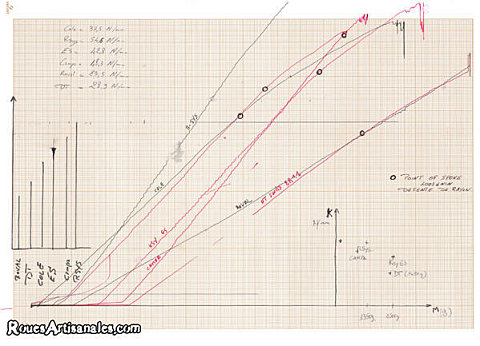

To prove the figures, Mavic had the good idea to bring the lateral stiffness machine. It’s linked to a tracing pencil via some sensors that represents the deviation of the wheel according to a load.

The results are on the picture below. The curve represents the lateral deviation under the load. The steepest is the curve, the stiffest is the wheel. The first curve representing the rear R-SYS is obviously the steepest. The others rear wheels all belong to the journalists. They aren’t wheels brought by Mavic for the test.

A comfort gain?

Even though it’s not an important parameter, Mavic claims some things about this. The vertical deviation of a wheelset is very small compared to how a tire can deforms. However it’s interesting to know how a difference in term of architecture modifies the frontal stiffness.

Thus, for the front wheel, the carbon spokes make the wheel harder since it is 100N/mm harder than a Ksyrium ES (from 1600N/mm to 1700N/mm). At the rear, the higher bracing angle allows a lower frontal stiffness that should, theorically, brings comfort. Rear wheel frontal stiffness is 1400N/mm while the Ksyrium ES is 1600N/mm. The alloy drive side spokes, play a role in this vertical softness. Tubular carbon spokes could have been used but vertical stiffness would reach a summum, meaning an obvious lack of comfort, according to Mavic.

Furthermore, because of their big diameter, the pushing drive side spokes bracing angle should have been reduced. The spoke tensions would then have been more unbalanced. Finally, the alloy spokes are more resistant if the derailleur enters the spokes… and they will cost less to replace.

They lack aerodynamic!

Obviously, from a speed point of view, these wheels are "slower" than the Ksyrium which weren’t the fastest either. The spokes are guilty, they are very large and offer a big contact with the air flow. Wheels overall drag is 1.35 times higher than the Ksyrium ES, and 1.57 times the the Cosmic Carbone Ultimate.

What about the dimensions?

In tubular version, both rims are 22mm deep. For clinchers, the front rim is as well 22mm while the rear one is 25mm for a better resistance between the two "bridges" of the rim. The rear rim is asymetrical to balance the spoke tensions on both sides of the wheel. Spoke count is 16 for the front and 20 for the rear.

Custom wheels?!

Each journalist present there had his wheels engraved with the name of the magasine. Beautiful!

Accessories.

With the wheels, you will find the tools to disassemble the ring allowing the compression of the spokes. The spoke key, the tool to hold the flat spokes, and the bearing key are included in the wheelbags.

The speedometer magnet is built around a spoke. Its position is easy to move.

In short…

The price is 1100 euros for the wheelset plus the accessories. The weight limit is 100kg.

To put it briefly, Mavic finally released a very innovative system. The concept is so easy and obvious that no other brand thought about it before. We hope to discover in a short time several modifications of this system to improve it again.

Well done yellow guys!