|

Pour la petite histoire, nous avons testé plusieurs paires de roues haut de gamme pour l’édition de Décembre du magazine “L’Acheteur Cycliste”. Les résultats étaient plutôt surprenants, en tout cas pour la paire de Lew Racing Pro VT-1 qui s’est avérée

plutôt médiocre en terme de rigidité latérale. Alors que le constructeur annonce une rigidité exemplaire, nous avons trouvé que ces roues étaient les plus souples, sous de fortes charges.

La rigidité était tellement faible que les rayons pliaient sous la charge. Nous pensions donc que ces roues étaient de la pure publicité grossière, surtout que nous n’avions pas pu les

essayer à cause du manque de disponibilité.

Quelques semaines après notre test, le magasine TOUR a publié son propre test, et révéla ces roues comme un sérieux adversaire aux Lightweight et Mavic CCU.

Nous étions donc partagé entre nos résultats et les leurs… où était la vérité?

En face de toutes nos questions et désillusions, Lew Racing a finalement pu nous dénicher une paire pour tester…sur la route. Nils, de Fairwheelbikes, qui

est leur représentant officiel en Europe, est passé il y a quelques jours avec son prototype des Pro VT-1 en version Tune (840g) pour

essai grandeur nature.

Après de courtes explications sur les roues et le démontage des moyeux, nous sommes partis pour une sortie de deux heures. Elle s’est avérée plutôt rapide et sportive, pour cette période

de l’année: le manque d’entraînement est évident. La vitesse moyenne était de 31/32km/h, mais les 10 derniers kilomètres ont été avalés à 40/45 km/h de

moyenne.

L’inertie: un niveau jamais atteint auparavant

La propriété la plus impressionnante de cette paire de roues est perceptible dès le premier coup de pédale. L’inertie atteint un niveau incroyablement bas, du jamais vu auparavant. Les accélérations sont très faciles et les premiers kilomètres sont même destabilisants.

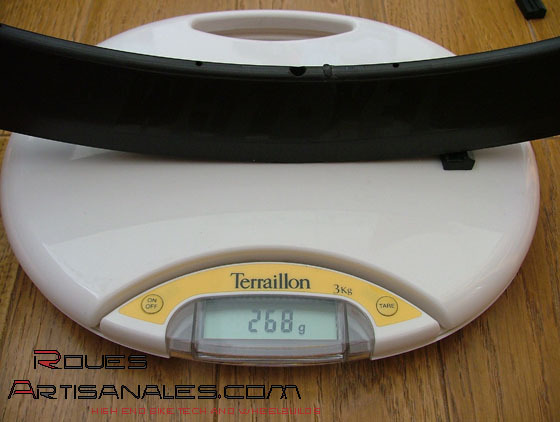

Même la paire de Lightweight 922g, testée il y a quelques mois, s’avérait un peu plus résistantes aux changements de rythmes. Ce phénomène inhabituel est causé par le poids exceptionnel

de la jante, qui ne pèse que 220g (270g en pièce détachée). En contre partie, cette faible inertie rend la direction très sensible et il est plutôt difficile de conserver une direction

toujours droite, à moins d’y être habitué. Qui plus est, le vent semble affecter un peu plus la direction, toujours à cause de la jante hyper légère et de sa hauteur (46mm)

Cliquez pour agrandir (955Kb)

La rigidité: adaptée au coureur…

Après quelques centaines de mètres, voyant la première pancarte pointant le bout de son nez en haut d’un petit faux plat, je n’ai pu résister à un premier

sprint sur un « bon braquet » pour juger un peu de leur rigidité en condition réelle. Les roues sont tout sauf souples car la jante n’a pas bougé entre les patins. Quand la forme est bien

meilleure pendant l’été, le résultat aurait été différent. Mais dans tous les cas, elles ont semblé rigides à souhait et le résultat publié par le magazine TOUR est sans doute plus proche

de la réalité que ce que nous avons trouvé. En réalité, notre test est tout aussi intéressant : nous avons réalisé à quel point ces roues s’avéreront souples pour des coureurs lourds et

costauds. C’est pourquoi Lew Racing propose la version Clydesdale, qui pèse 1050g, pour les coureurs de plus de 85kg et jusque 113kg (voyez ici)

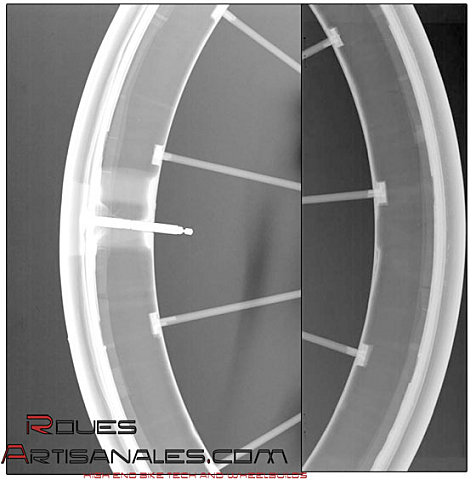

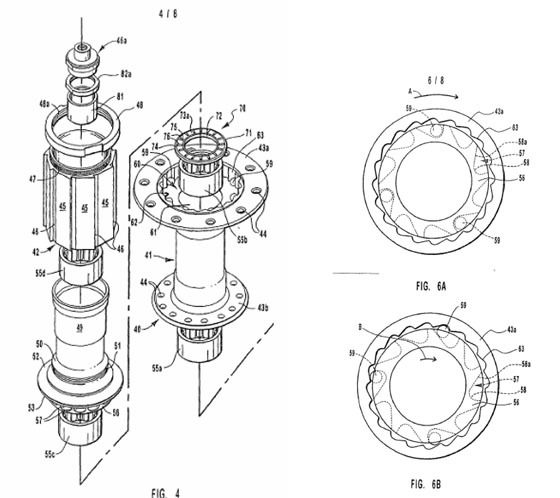

Questioné, Paul Lew, directeur et ingénieur chez Lew racing et Lew Aerospace, nous explique les dessous du design des roues. Il semble que ces roues soient

conçues et pensées selon des méthodes jamais explorées par les autres constructeurs. Sur des roues conventionelles, pendant les accélérations, la jante a tendance à s’approcher des patins

à cause du transfert du couple: des rayons tirent la jante et gagnent en tension, quand d’autres la pousse et perdent de la tension. À cause de la différence de parapluie entre les deux

flasques, une distorsion apparaît et la jante se déplace entre les patins. Sur ces roues très spéciales, le flasque central parfaitement dans l’axe de la jante, transfère tout le

couple et empêche les différences, à ce niveau, entre les deux flasques extérieurs. Ainsi, la roue ne se déforme pas. C’est ce qui se passe lors des accélérations.

En montagne, à cause de la basse vitesse et de l’angle vélo/sol plus élevé, la force latérale qui pousse la jante vers la gauche et la droite est plus

importante, donc les roues pourraient s’avérer moins rigide. Nous espérons pouvoir tester une autre paire de Pro VT-1 plus longtemps, et pendant l’été pour en savoir plus…

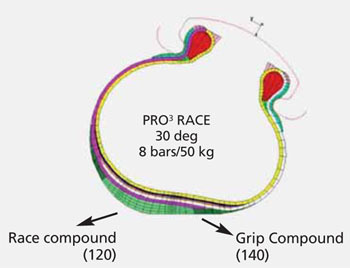

Le rendement… avec des boyaux Dugast

Les roues étaient équipées de boyaux Dugast, peints en noir pour assortir les roues. Bien que les sensations de rendement soient purement subjectives, avec des

dizaines de paramètres qui influent, j’ai trouvé les roues particulièrement confortables sur les routes dégradées. Les vibrations n’arrivent pas comme d’habitude à la selle et au cintre,

elles semblaient plus absorbées. Est-ce causé par la faible rigidité frontale? La structure carbone/bore apporte t-elle ceci? S’agit-il simplement des boyaux? Difficile d’apporter une

réponse, mais dans tous les cas, ces roues sont très agréables.

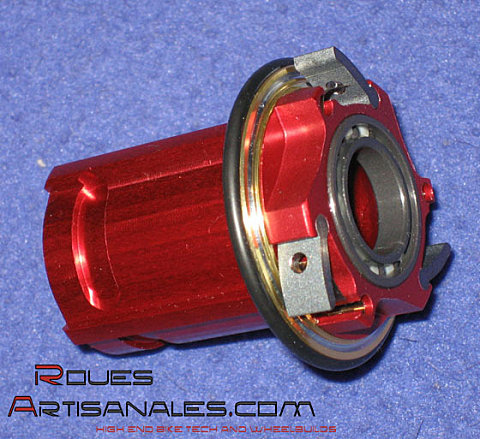

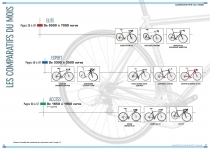

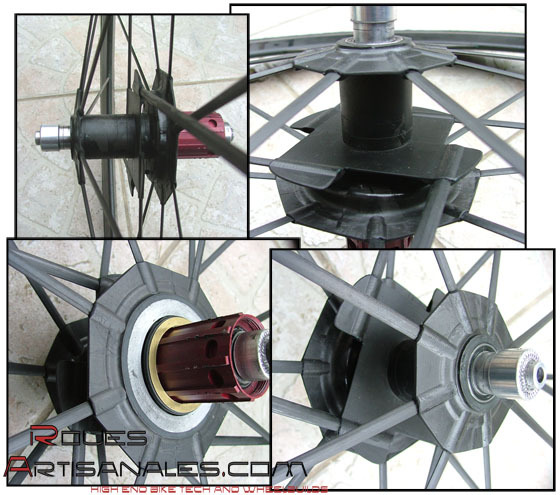

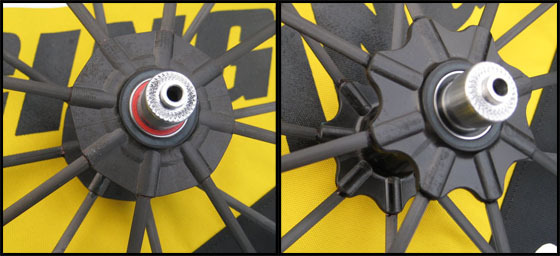

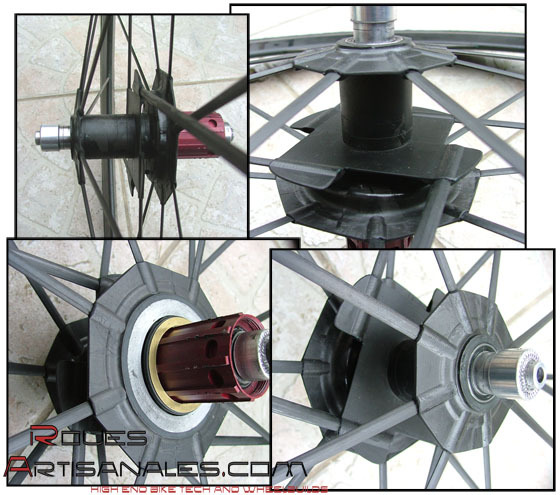

La résistance des roulements: moyeu en phase de développement?

Les roulements utilisés sur ces roues sont spéciaux. Bien qu’il s’agisse de billes céramique d’excellente qualité, associées à des cages et portées en acier,

ils sont plutôt « secs ». J’entends par là qu’ils sont très faciles à tourner mais des interférences sont perceptibles en tournant l’axe à la main. Ceci est causé par l’infime quantité de

graisse pour réduire la résistance à l’avancement et ainsi gagner quelques précieux watts pour plus de vitesse.

Cliquez pour agrandir (1118Kb)

Les roulements sont insérés dans le corps en carbone/bore et les axes sont glissés entre

les portées intérieures des roulements. L’espacement du moyeu et le réglage du jeu sont réalisés par des cales, des rondelles. Bien que ceci fonctionne, les mécanismes de ces prototypes

semblent encore en phase de dévelopement et devraient recevoir des améliorations importantes. Premièrement, il y a toujours du jeu entre les patins de freins, quand la roue est installée

et les attaches m²racer 38g sont sérrées. Ce n’est pas perceptible sur la route mais une solution mériterait d’être trouvée.

Deuxièmement, Lew racing ne conseille que 3 modèles d’attaches rapides compatibles avec leurs roues. Elles apportent suffisamment de force de compression pour éviter le jeu. De telles

restrictions ne devraient pas exister si les mécanismes des moyeux étaient correctement conçus. Troisièmement, le roulement de la roue arrière des roues que nous avions testé en

laboratoire était anormalement résistant, en charge.

Donc la force de compression doit être forte pour éviter le jeu mais pas trop forte pour éviter de perdre de la puissance dans les roulements… notre champ de sélection des attaches est

fortement réduit.

Récemment, Lew a sorti la version finale des roues équipées du mécanisme Tune. Les problèmes de jeu et de résistance des roulements en charge, sont résolus.

Encore une fois, nous espérons pouvoir tester une nouvelle fois les roues.

Click to enlarge (969Kb)

Finition et apparence

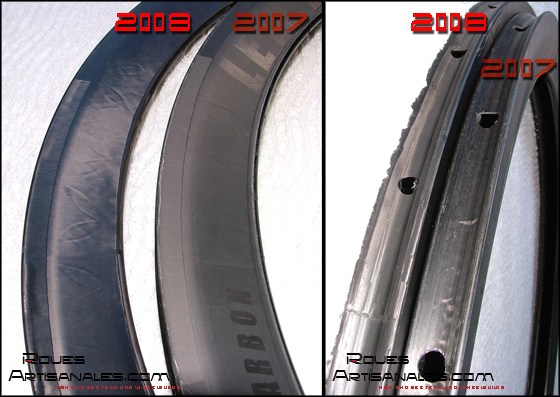

La paire que nous avions disposé pour notre test labo était une des premières fabriquées, la finition était franchement indigne d’une paire de roues de ce

prix, sans doute à cause de la difficulté à travailler la fibre de bore. Les formes spécifiques, en particulier celles du moyeu arrière et des bords de la jante, contribuent sans

doute à ce manque de finition.

Pour faire simple et clair, les moyeux n’étaient pas ronds, leur surface n’était pas régulière, la jante manquait de matière à différents endroits, la colle verte était visible,

etc.

La dernière version, celle que nous avons testé sur la route, bien qu’encore à l’état de prototype était bien mieux finie. Lew Racing a véritablement fait un

effort à ce niveau et il semble qu’ils travaillent la fibre de bore bien plus facilement. Les moyeux, au même titre que les jantes, s’approchent de ce que l’on est en mesure d’attendre de

la part d’un produit à 4600/5000 euros.

La technologie au service de la performance!

|

Paul

Lew

http://www.ncet.org/tban/

|

Les Lew Racing PRO VT-1 repoussent encore un peu plus loin les limites. Très légères avec seulement 820/840g en version Tune, elles sont aussi aérodynamiques et très rigides pour un coureur

léger (65kg). Les matériaux, la structure, le concept sont autant d’avancées technologiques. Nous aimerions dire qu’il s’agit de la révolution mais beaucoup de constructeurs semblent abuser

de ce qualificatif. Nous dirons simplement que ces roues, bien que ce soit un peu fort, écrasent et envoient au tapis n’importe quelle roue actuellement sur le marché. Cependant, bien

qu’elles soint sur la voie de la perfection, les moyeux doivent encore être améliorés, particulièrement en ce qui concerne le jeu et le réglage de l’espacement entre les pattes de cadre et

fourche.

Quand les vendrez vous à 2500 euros au lieu de 5000? J’en acheterai 3 paires!

Qu’est-ce qui est bon, qu’est-ce qui l’est moins?

|

+

|

–

|

|

Les accélérations les plus faciles

|

Direction très sensible

|

|

Les roues les plus légères sur le marche

|

Mécanisme des moyeux (sur notre paire proto)

|

|

Look furtif, classe, prototype

|

Finition plutôt approximative

|

|

Des roues révolutionnaires

|

Disponibilité

|

|

Le service client

|

Prix

|

Articles Roues Artisanales précédents:

– Lew Racing, version Clydesdale

– Lew Racing VS Lightweight Standard VS Mavic CCU

– Lew Racing, les jantes 2008

– Campagnolo 2008, Lew Racing, Colnago 2008

– Lew Racing wheels, qu’est-ce qui les rend si attrayantes?

– Lew Racing, M5: les jantes sont sorties

– Lew PRO VT-1: les nouvelles roues

|