Unveiled during 2009 Eurobike, AX-Lightness rims are finally available as stock wheels and nude rims. We bought some of them for testings and eventually to offer them in our pro RAR boutique.

We have been very pleased with this item The finish is exceptionnal for such a light product. The 24mm rims – claimed to be limited to a 110kg rider – have all been weighted under 195g in the two versions: 20 and 24 holes.

Beside the outstanding finish, rarely met on such lightweight items, there are three interesting features and technologies coming along with them.

- – First of all an aramid layer is applied at the spoke nipple area. This increases the spoke tension resistance and this makes both the wheelbuilding and the truing adjustements

easier since the nipple rotates smoothly on its pivot spot. Theorically the rims are not limited in tension (or at least the tension limit of the hub). Practically, 1300N will be a

significant tension for such a lightweight item.

Three aramid layers are also taking place underneath the brake track.

- – Second, the manufacturer logos are molded on the rims. The peeled off stickers are not possible with these beauties. You will have to leave, at least, the three AX logos per face.

The stock wheels also receive stickers adding 10g per rim.

- – Third, the rims still have the bladded, meaning a pulsing less braking.

Basically to make a carbon rim, the manufacturers can follow several ways ending in two methods.

Either the rim is made onto a structural foam like Corima, Mavic, Aerozenith and some giant taiwanese companies do. This method, being the easiest, make the rims heavier but also generally stiffer.

The second method is more expensive, the rim is made onto a bladder and is placed into the oven under high pressure/temperature.

Some rim makers remove this bladder post production to save weight, this is the case of Edge Composites or Lew Racing. Unfortunately this tends to leave a brake pulsing on the light rims because it remains a weak spot on the brake track. Even when the hole made to remove the bladder is filled, it remains width variations or they appear with the time. Most of the time this pusling is so low that the braking remains smooth. Sometimes it is dangerous to brake at high speeds.

At AX-Lightness, the plastic bladder is left in the rim. Like Reynolds or Zipp, they didn’t want to affect the function. However they are able to make it happen to save further

weight, without making a hole in the rim.

This product seems promising and very different from the lightweight rims we are used to see. They are perfectly finished which is rare.

We hope to start the very first tests around Christmas and during January. We hope the salt of the roads will wear fastly the rims so we quickly know what we can expect from them.

Ax also has a 42mm rim in its range, the finish and technology is as promising. This rim however only is available in 16 and 20 holes at the moment, the 24h mold being on the way to be machinned. This 42mm rim is 260g without stickers. It also is limited at 110kg.

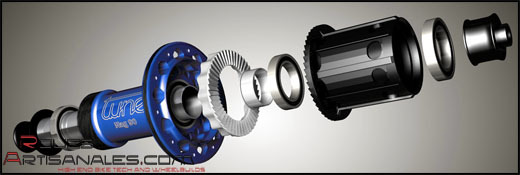

Tune Mag90

As exclusivity for you, the latest anorexic component thought by Uli Fahl is visible below:

This special hub do not feature a mechanical but a magnetic spring. It will be available by the end of 2010. The wheels built by Tune will receive this new system earlier in 2010.

The Mag90 geometry is the same as the current Mag150. The overall hub shape remains similar although extra machinnings lighten the hub shell.

Internally, the hub is completely redesigned:

– 17mm alloy axle

– 6803 bearings instead of 6802

– spur gear system with only 2 mechanical pieces: the freehub body and the sliding disk.

This super svelt should be in everyone’s mouth very soon…