It’s thursday, the first day of Eurobike. Zipp Speed Weaponry welcomes the journalists to their press-conference, where they will present the 2008 line-up. For us,

it turned out to be the first real highlight, since we didn’t know what expect and were quite surprised by some of the new stuff.

Zipp totally live up to their name. It’s obvious, this year’s main goal of most companies was weight-reduction. Lightweight and LEW introduced sub-800 and sub-900 gram wheelsets, the

frame-builders shave more and more weight off their rigs, too, and broke the 800 gram barrier and the first complete groupset below 2kg hit the market.

Not so Zipp – at least concerning their wheels. Yes, their wheels are light (Heck, actually, their disc is one of the lightest available!) and you will not be able to blame them,

when you’re training buddies leave you behind on the climbs, but still, their main objective was – and remains – to increase the aerodynamical properties of their hoops and their resistance

too.

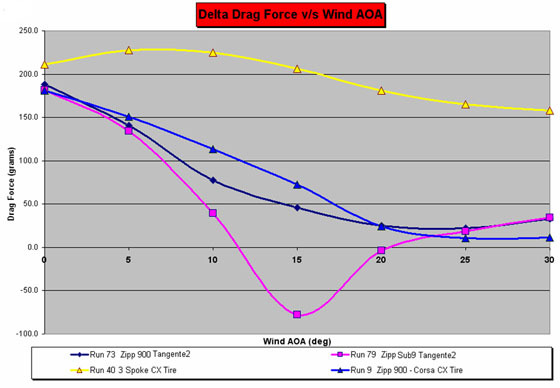

They are well-known for the effective collaboration with Team CSC and excessive wind-tunnel testing. All Zipp wheels are designed to offer the perfect wind-cutting properties

under certain angles – the most likely ones of course, which are between 10 and 20°. (See a diagram further below)

Now there’s just one question to be answered: Have Zipp worked on the weakness of their rims – the impact resistance? According to Andy Paskins, they did…. with

great success.

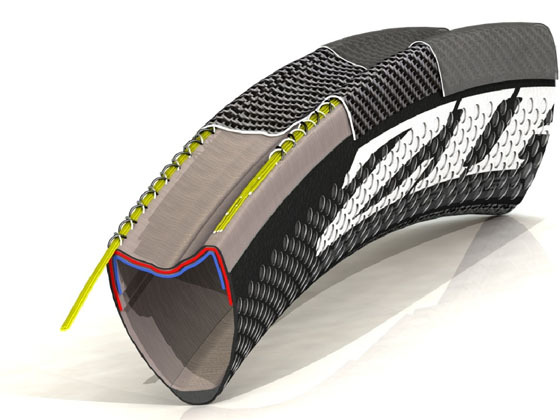

A new technology, called “Carbon Bridge” helps Zipp to create rims with 28% higher impact resistance

than any other rim ever made at this weight. It’s making the rims so strong, that Zipp actually removed fibre layers from the rim-bed to keep the weight on the same level as

previous models. Usually, rims rely on 2-dimensional layup technique, while the layers are beeing held together by a special resin. In most cases of rim failures, it’s not the fibres that fail,

but the resin that holds them together. What Zipp did, is adding some kevlar, but not in the same way many other companies do it, because it wouldn’t solve the actual

problem.

They “have added Kevlar thread in a co-axial helix stitch to bind the layers together in all 3 dimensional planes. The Kevlar is holding the carbon together and distributing the impact

force 3-dimensionally throughout the plies of carbon. Further, the Helix stitched carbon serves as capstone at the top of each outside diameter bridge, distributing the compressive forces

down to the rim.”

handlebar with matching brake-levers and new, deeper Flash-Point wheels.

Zipp’s

climbing wheelset has received a complete overhaul for 2008. Deeper rims (32mm now), more aerodynamic rim shape, Carbon-bridge technology and savingsof 4-6 watt over previous 202. The weight will remain the same (1060 grams). The new Zipp 202 are the first ever low-profile climbing wheelset developed in the

wind-tunnel.

disc up to 13° angle to the wind. It doesn’t only save 29 seconds over a trispoke in a 40Km time-trial, but also weighs 80grams less.

At 15° (so called sweetspot), which is the most likely angle your wheels will have to the wind, the sub-9 achieves a -80 grams drag reading.

VumaQuad crankset

2 years after the Zipp 300 crankset hit the market and made some big weaves, its big brother, the VumaQuad has even higher aims. Thecontemporary oversized outboard bearings and integrated spindle provide extremely high stiffness values. Actually, the aluminium spindle has a large enough diameter, to stick the spindle of the

already super-stiff DuraAce crankset through it.

The featherweight carbonfibre crankarms come in a special 4 arm design with Zipp’s very own FEA designed US manufactured chainrings, available in 34/50 or 39/53.

The US made bearings has 17% higher fatigue life than traditional external BB bearings thanks to a super high-quality grease from Japan.

The crankset (incl. All the hardware, chainrings, bearings and BB cups) hits the scale at a mere 560 grams! Compare that to currently lightest availble cranks – the Clavicula – which is

only 10 grams lighter, when used with Stronglight’s CT² chainrings. Please consider, Zipp claim the VumaQuad is 33% stiffer than the next-lightest competitor.