This year, two new lightweight and high-end wheelsets hit the market, certainly to face up Carbon-Sports and Lightweight wheels supremacy. Lew Racing has announced on the 27th of January its Pro VT1 and Mavic, its Cosmic Carbon Ultimate the 15th of February. Both of them have serious assets related to the material, the technic, the service or the price to intimidate the well known and famous german brand.

Mavic simply modified Lightweight wheels’ Heinz Obermayer concept. There is a truing system on the rear wheel, differents shapes and materials for the hubs and the rims. The main process still remains the same: the spokes are laminated as one piece inside the rim and are wrapped around the hub. If a spoke is broken, the wheels are unusable, they can be put with the waste! They cost more than 2300 euros for the Mavic and 2600 or 3600 for the Lightweight Standard and Obermayer, the bill is quite high…

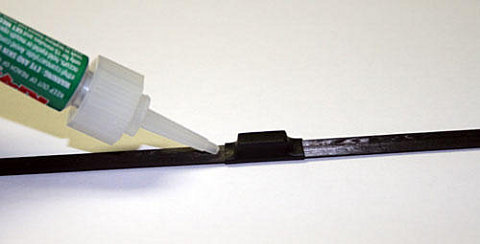

| Broken spoke around the hub notch | |

|

The advantage of Lew Racing wheels is about the possibility to replace any part of the wheel: the spokes, the hub or even the rim. This is possible thanks to the manufacturing process that is totally different from the two sets we spoke about above. Here, the spokes are bonded inside the notches of the hub and the rim via a specific agent. They provide the stiffness and the integrity of the wheel when the manufacturing process is ending. Indeed when a spoke has been damaged, Lew Racing removes it by heat, internal pressure and external force. A reactive agent is used to completely remove any trace of bonding product at the spoke/hub and spoke/rim interface. |

|

|

Repaired spoke

|

|

|

Then, a brand new spoke is replaced and bonded, just like it was destinated to a new wheel. |

|

As comparizon, you can realize the differences between the three wheelsets thanks the following table:

| Lew Racing PRO VT1 | Lightweight Generation 2 | Mavic Cosmic Carbone Ultimate | |

| Rims | – 46mm deep – Carbon / Boron -230 g – swirl generator lip |

– 53mm deep -Carbon 3K – approximately 290-320g |

– 40mm deep – Carbon 12K – the rear is assymetrical |

| Spokes | -16 front / 20 rear – Carbon / Boron – NACA 0029 airfoil section (aeronautic comitee) – 3g |

– 12-16-20 front / 20 rear – Carbon / Kevlar |

– 20 front / 20 rear – Carbon – Truing and adjusting system on the non drive side of the rear wheel |

| Hubs | – Carbon / Boron – Rear hub has 3 flanges, the two exteriors for the stiffness and the cantral one to transfer the torque – boron axles, 15mm of diameter |

– Carbon 3K for both front and rear hubs – alloy front axle: 15mm of diameter, carbon rear axle: 15mm of diameter |

– Front is Carbon 12K – Rear is made out of alloy – alloy 9mm of diameter axles |

| Manufacturing process | Lamination / Bonding | Lamination / moulding | Lamination / moulding |

| Carbon brake pads | No | Yes | Yes |

| Wheelset weight | 880 to 920g (Shimano and Campagnolo versions) | 915 à 1090g (super light 12/20 Obermayer version and Standard 20/20 version) | 1185g |

| Service | Each part is serviceable, a 4 year "No question asked" warranty extension programm is available for a complete replacement. It costs US$1000 | The rims is sometimes reparaible. Otherwise, there is a 30% discount on a complete new wheel | MP3 extension programm warranty. Complete replacement under certain condition |

| Price | 4100 euros (5500 dollars) | From 2600 (3500 dollars) for the Standard to 3600 (5500 dollars) euros for the Obermayer | 2300 euros (2700 dollars) |

– Aerodynamics Lew Racing Pro VT1 wheels are thought and designed into every single detail. They feature several new concepts. Aerodynamical properties seem to have been a priority during the conception of the wheel: a swirl generator lip on the 46mm deep rim and the NACA 0029 airfoil section spokes improve the drag properties of the wheels.

|

Click to enlarge |

|

Click to enlarge |

|

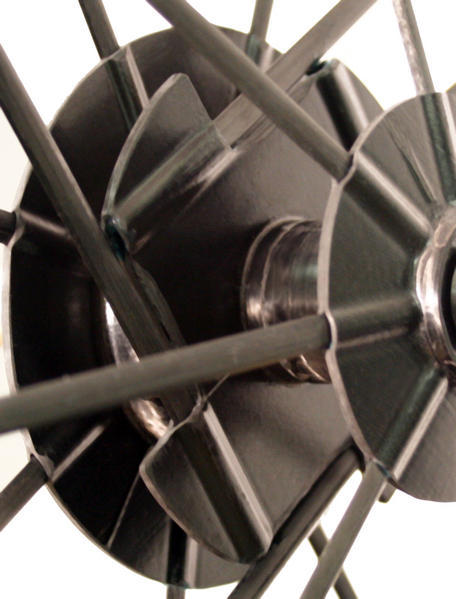

– Torque transfer

Another interesting feature is about the rear hub. To transfer the torque, we usually cross the rear wheel spokes as much as we can to place them as tangential to the rear hub. Because of the bracing angle, they are not in the same plane as the rim and so they get useless stress. With this special design, the rear wheel has the advantages of both the high bracing angles bringing superior stiffness and the zero degree bracing angle providing the perfect torque transfer…

| Rear hub, triple flanged | |

|

The rear hub is triple flanged: the two exterior ones are far from each other (60.61mm, Lightweight width is 58mm and Mavic CCU width is 55mm) and receive radial spokes for a maximal stiffness. The central one gets four spokes 25% oversized. They are tangential to the hub to transfer the torque generated by the rider. This flange is placed perfectly in the same plane as the rim to force the spokes working only in traction and to prevent them from bending. |

|

Click to enlarge

Photo ©: Fairwheelbikes.com

|

Click to enlarge

Photo ©: Fairwheelbikes.com

|

Click to enlarge

Photo ©: Fairwheelbikes.com

|

|

|

Click to enlarge

Photo ©: Fairwheelbikes.com

|

|

– An excellent stiffness, in theory

One thing is sure, thanks to several things, related to the architecture and the material used, in theory the wheels are very stiff. The distance between the flanges of the hub is high, it reduces the rim movements between the brake pads while accelerating. Then, the second reason for stiffness is due to the spokes. Fully inserted at the bottom of the hub and rim notches, they are then bonded inside their compartment. Five times as stiff as the traditionnal stainless steel spokes, they are as well three times more resistant to compression and double the tensile strength. These properties mixed to their full insertion at the bottom of the notches allow them to work both in compression and traction (Mavic isn’t innovator on this concept though). Thanks to this, even with very low spoke tensions the stiffness should remain high.

We are impatient to get the wheels to test them in laboratory…

– Weight, inertia & sturdiness

Beside all these features Paul Lew introduced on his wheels this year, the overall weight of the wheelset is between 880 and 920g… which is very low. This weight can be reached thanks to the carbon/boron material and the special DEX-LCM™ technique developped for the American department of defense. About the inertia, the Lew wheels rims weight only 230g while their height is 46mm. It means they should be incredibly easy to accelerate. As comparizon, Lightweight rims weight is between 290 and 320g.

Last but not least, the spoke tension in these wheels is very low. Therefore, even with a broken spoke, the wheel remains true, with no hoop nor big change in stiffness or behaviour. This is another breakthrough in wheel functionning…

| Interview of Paul Lew, engineer and designer of Lew Racing PRO VT1 (11,8Mb) |

Thus…

Paul Lew wheels definitely have an enormous advantage over the Lightweight wheels and Mavic CCU whose design is very efficient but is growing older and is almost impossible to repair.

Mavic, with its MP3 program replaces the Cosmic Carbon Ultimate for 185 euros. Carbon-Sports proposes a 30% discount on a new wheel. Here, for the Lew wheels there is only to remove the broken spoke then bond a new one… which is far cheaper than a complete replacement for both the customer and the company.

The only disadvatange of Lew wheels is that they are some hundreds extra euros!

– Hub servicing

| Rear hub disassembly (11.8Mb) |

| Rear hub assembly (7.18Mb) |

– Spoke magnet